You can find more information here

1. General information

The hydrogen sulfide (sour gas) produced in petroleum or natural gas refineries is often processed into elemental sulfur in plants named after their inventor, “Claus.” Sour gas and hydrogen have the ability to diffuse through gas-tight protective tube materials at high temperatures.

These substances damage precious metal thermocouples.

The temperature assemblies in this series protect the thermocouples with protective gas. Nitrogen is generally used for this purpose. Protection can be provided by static internal pressure or, better still, by a flushing circuit.

The preferred thermocouple material is type B (Pt30Rh-Pt6Rh). The high rhodium content in both thermocouple legs results in better corrosion resistance.

The disadvantage is a high measuring range start at approx. 400 °C.

When using a purging system, thermocouples S (Pt10Rh-Pt) and R (Pt13Rh-PT) can of course also be used.

2. Type series

Depending on the rinse used, we have the following types in our program:

- TFC41 – with protective gas atmosphere through static internal pressure

- TFC42 – Protection of the thermocouple(s) by flushing circuit

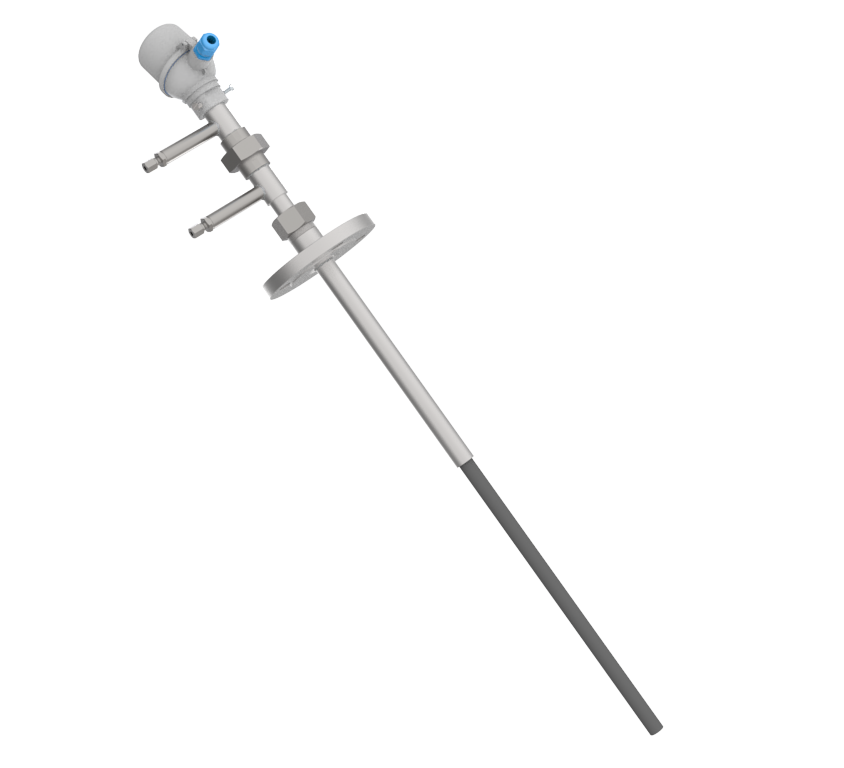

3. Basic structure

Basic properties are described in our product data sheet 1113.01 – Thermocouples for industrial furnaces. This data sheet only deals with design-specific features.

All A-type connection heads can be used. Double elements with 2 transducers are possible by using a rim housing instead of a connection head.

Only high-purity aluminum oxide C799 can be used as the protective tube material. For a second outer protective tube, silicon carbide has proven to be very robust.

4. Process connections

These devices are exclusively flanged. Due to their design, the flange size must be at least DN40 or 1 1/2″. The preferred flange sizes are DN50 or 2″.

5. Additional equipment

If there is no purge connection on the flange nozzle of the combustion chamber, one can also be integrated into the process connection flange.

6. Type descriptions

6. 1 Type TFC41 – Thermocouple fitting with static internal pressure

The thermocouple is protected by a stationary protective gas atmosphere, preferably nitrogen. This can gradually become contaminated through diffusion processes.

Therefore,only relatively corrosion-resistant type B thermocouples can be used for this design.

The protective tube is made of gas-tight, high-purity aluminium oxide type C799 and should have a diameter of at least 15 mm. If an additional outer protective tube is used, the diameter may be smaller.

6.2. Type TFC42 – Thermometer fitting with flushing circuit

Permanent purging reliably protects the thermocouple from sour gas. This enables the use of thermocouples with a pure platinum leg, types R and S. These may be required for SIL measurement circuits in conjunction with transducers. The purge gas flows through the insulating rod capillaries to the hot end and back again around the outside of the protective tube.

With regard to the protective tube itself, the information provided in section 6.1 applies.

6.3 The appendix shows examples that have been realized and proven in use

Böhme + Ewert GmbH’s application technology department will be happy to provide you with further advice.